Notes:

New band saw blades tend to vibrate and emit vibration noises. In this case, reduce the cutting speed (m/min.) until no more vibration can be heard.

After breaking-in, slowly increase the cutting speed (m/min.) to the determined value and then gradually increase the feed speed (mm/min.) to the determined value based on the cutting data table, cutting data slide or ParaMaster®

When using for the first time, WIKUS always recommends that the

- Band tension is 250 - 300 N/mm²

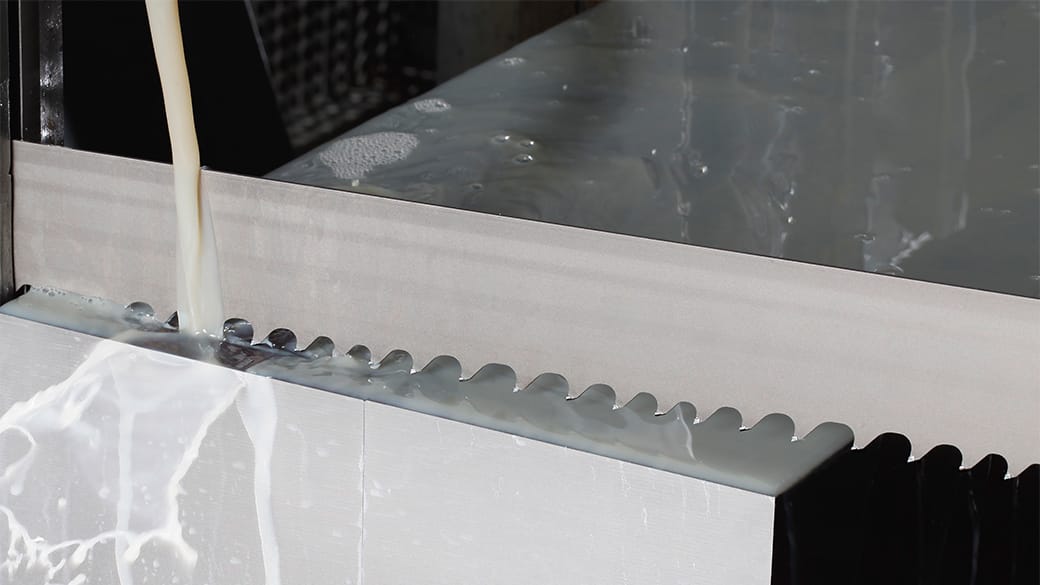

- The oil content of the coolant must be checked with a hand refractometer, and the required oil content should be adjusted if necessary.

- The recommended oil content of the cooling lubricant can be found in the cutting data slide rule or in ParaMaster®